Mid West Instrument

Backflow Testing & Recertification

Backflow testing and recertification for municipal and other governmental requirements are central product and service areas for us at Specialty Valve & Controls. We are a sales and service center for Mid West Instrument which is the leading manufacturer of backflow testing equipment.

For the past 30 years Mid-West Instrument has been producing Quality Backflow Test Kits that have set the standard in the industry. Our Model 830 has been the benchmark of the industry for decades. Constant input from field testers led to refinements such as inline filters, laminated test procedures, removable lids, soft seated needle valves & line pressure gauges.

Accessories

Offering the full line of Mid-West Instrument accessories for their backflow testing products.

From replacement parts, cleaning kits, adapters, hose assemblies, filters and carrying cases, we have everything that you need to keep your backflow testing equipment running at optimal performance.

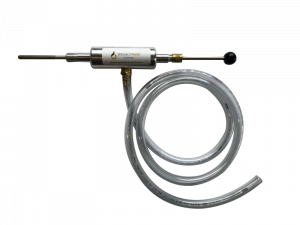

- Install the Test Clean into the plugged test cock

- Open test cock and depress plunger to clear the obstruction

- Back out plunger and flush debris into a bucket or floor drain

- Remove the Test Clean and proceed with testing

- Soft Seated Needle Valve

- For USC Test Procedures

- 15″ X 1/2″ Dia. Tube/Test Cock Adapter Assembly*

- 15″ X 1/2″ Dia. Extension Tube Assembly*

- 15″ is Assembled Length

Designed for hand tight connection of Differential Pressure Test Gauges to Backflow Prevention Assemblies. No wrenches or Teflon tape required.

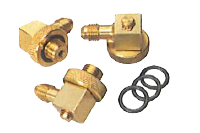

90º Swivel Fittings – Rotate 360º after installation

1/4″ NPT Quick Connect 1/4″ Flare

Ideal for tight spaces

Set includes:

- (3) 90º Swivel Fittings

- (3) 1/4″ NPT Quick Connect 1/4″ Flare

- (3) Spare O-rings

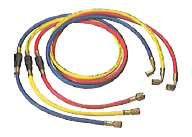

Model 830 – Five Foot Replacement Hose Assembly Kit. Set of 3 – (Red, Yellow, Blue)

- 1/4″-90º Hex Flare

- 1/4″ Straight Quick Coupler

- Field serviceable filter housing

- Filters included

Fits Model 844/845 – Five Foot Replacement Hose Assembly Kit.

- Set of 3 – (Red, Yellow, Blue)

- 1/4″ Straight Quick Coupler – Both Ends

- Field servicable filter housing

- Filters included

Filter Assembly Adapter Kit for Test Kit Hoses that do not have filters.

- Set of 3 – 12″ hoses.

- 1/4″ Quick coupler x 1/4″ Flare Connection.

- Field servicable filter housing

- Filters included

Replacement Filter Element Kit – Set of Six

Test kit Case with Foam

(NOTE: Adapters shown to illustrate storage usage, not included)

Quick connect test fitting kits are designed for hand tight connection of differential pressure test gauges to backflow prevention assemblies. Quick connect fittings with ¼” flare make installation fast and easy. Kit comes with three sizes, ¼”, ½”, and ¾” NPT and contains three of each size.

Comes in a black clamshell case.

90˚ Swivel fittings rotate 360˚ after installation and are ideal for tight spaces. Quick connect fittings with ¼” flare make installation fast and easy. Kit comes with three sizes, ¼”, ½”, and ¾” NPT and contains three of each size.

Backflow Test Kits

Specialty Valve is a stocking distributor of all the Mid-West backflow testing products.

This includes the Mid-West 830, 835, 845-3, and 845-5 units that adds field flexibility never before seen in the backflow testing industry. All the Mid-West products have a 5 year warranty as noted and described below. Specialty Valve also keeps a stock of the accessory products to assist the tester, making their life easier.

When it comes to backflows, Specialty Valve is your one source company you can rely on to have the products, accessories, repair services, and a complete unit recertification program at your fingertips.

Standard Specifications:

Gauge Type: Diaphragm Differential Pressure

Gauge Dial Size & Range: 41⁄2″ 0-15 P.S.I.D./100 kPa DP Gauge with an 11⁄2″ Line Pressure Gauge

Differential Pressure Accuracy: ±0.2 P.S.I.D. (Descending)

Working Pressure: 200 P.S.I.G.

Body Material: Glass Reinforced Engineering Thermoplastic

Wetted Internals: EP Elastomers, Brass and 316 S.S. Metal Parts (Nylon Tubing on 830)

Valves: Soft-Seated Needle with replaceable seats

Hoses & End Fittings: Nitrile jacket and liner, Schrader 1⁄4″ brass coupler, inline field serviceable filters

Carrying Case: Durable Molded Plastic

Hose Length: Three each / 5′ long (color-coded)

Bleed Tube: One each / 4′ long clear (845-5 and 830 only)

Filters: Test kit is protected with 90 micron filters to minimize plugging with scale, sand, etc. Elements can be cleaned or replaced.

Adapter Fittings: Three sets of brass fittings provided for hookup to all standard size test cocks.

Temperature Limitations: Maximum 150°F/65°C. FREEZING TEMPERATURES MUST BE AVOIDED!.

Standard Specifications:

Gauge Type: Diaphragm Differential Pressure

Gauge Dial Size & Range: 41⁄2″ 0-15 P.S.I.D./100 kPa DP Gauge with an 11⁄2″ Line Pressure Gauge

Differential Pressure Accuracy: ±0.2 P.S.I.D. (Descending)

Working Pressure: 200 P.S.I.G.

Body Material: Glass Reinforced Engineering Thermoplastic

Wetted Internals: EP Elastomers, Brass and 316 S.S. Metal Parts (Nylon Tubing on 830)

Valves: Soft-Seated Needle with replaceable seats

Hoses & End Fittings: Nitrile jacket and liner, Schrader 1⁄4″ brass coupler, inline field serviceable filters

Carrying Case: Durable Molded Plastic

Hose Length: Three each / 5′ long (color-coded)

Bleed Tube: One each / 4′ long clear (845-5 and 830 only)

Filters: Test kit is protected with 90 micron filters to minimize plugging with scale, sand, etc. Elements can be cleaned or replaced.

Adapter Fittings: Three sets of brass fittings provided for hookup to all standard size test cocks.

Temperature Limitations: Maximum 150°F/65°C. FREEZING TEMPERATURES MUST BE AVOIDED!.

Standard Specifications:

Gauge Type: Diaphragm Differential Pressure

Gauge Dial Size & Range: 41⁄2″ 0-15 P.S.I.D./100 kPa DP Gauge with an 11⁄2″ Line Pressure Gauge

Differential Pressure Accuracy: ±0.2 P.S.I.D. (Descending)

Working Pressure: 200 P.S.I.G.

Body Material: Glass Reinforced Engineering Thermoplastic

Wetted Internals: EP Elastomers, Brass and 316 S.S. Metal Parts (Nylon Tubing on 830)

Valves: Soft-Seated Needle with replaceable seats

Hoses & End Fittings: Nitrile jacket and liner, Schrader 1⁄4″ brass coupler, inline field serviceable filters

Carrying Case: Durable Molded Plastic

Hose Length: Three each / 5′ long (color-coded)

Bleed Tube: One each / 4′ long clear (845-5 and 830 only)

Filters: Test kit is protected with 90 micron filters to minimize plugging with scale, sand, etc. Elements can be cleaned or replaced.

Adapter Fittings: Three sets of brass fittings provided for hookup to all standard size test cocks.

Temperature Limitations: Maximum 150°F/65°C. FREEZING TEMPERATURES MUST BE AVOIDED!.

Standard Specifications:

Gauge Type: Diaphragm Differential Pressure

Gauge Dial Size & Range: 41⁄2″ 0-15 P.S.I.D./100 kPa DP Gauge with an 11⁄2″ Line Pressure Gauge

Differential Pressure Accuracy: ±0.2 P.S.I.D. (Descending)

Working Pressure: 200 P.S.I.G.

Body Material: Glass Reinforced Engineering Thermoplastic

Wetted Internals: EP Elastomers, Brass and 316 S.S. Metal Parts (Nylon Tubing on 830)

Valves: Soft-Seated Needle with replaceable seats

Hoses & End Fittings: Nitrile jacket and liner, Schrader 1⁄4″ brass coupler, inline field serviceable filters

Carrying Case: Durable Molded Plastic

Hose Length: Three each / 5′ long (color-coded)

Bleed Tube: One each / 4′ long clear (845-5 and 830 only)

Filters: Test kit is protected with 90 micron filters to minimize plugging with scale, sand, etc. Elements can be cleaned or replaced.

Adapter Fittings: Three sets of brass fittings provided for hookup to all standard size test cocks.

Temperature Limitations: Maximum 150°F/65°C. FREEZING TEMPERATURES MUST BE AVOIDED!

Standard Specifications:

Gauge Type: Diaphragm Differential Pressure

Gauge Dial Size & Range: 41⁄2″ 0-15 P.S.I.D./100 kPa DP Gauge with an 11⁄2″ Line Pressure Gauge

Differential Pressure Accuracy: ±0.2 P.S.I.D. (Descending)

Working Pressure: 200 P.S.I.G.

Body Material: Glass Reinforced Engineering Thermoplastic

Wetted Internals: EP Elastomers, Brass and 316 S.S. Metal Parts (Nylon Tubing on 830)

Valves: Soft-Seated Needle with replaceable seats

Hoses & End Fittings: Nitrile jacket and liner, Schrader 1⁄4″ brass coupler, inline field serviceable filters

Carrying Case: Durable Molded Plastic

Hose Length: Three each / 5′ long (color-coded)

Bleed Tube: One each / 4′ long clear (845-5 and 830 only)

Filters: Test kit is protected with 90 micron filters to minimize plugging with scale, sand, etc. Elements can be cleaned or replaced.

Adapter Fittings: Three sets of brass fittings provided for hookup to all standard size test cocks.

Temperature Limitations: Maximum 150°F/65°C. FREEZING TEMPERATURES MUST BE AVOIDED!

For the past 30 years, Mid-West Instrument has been producing Quality Backflow Test Kits. Our Model 830 has been the benchmark of the industry for decades. Constant input from field testers led to refinements such as inline filters, laminated test procedures, removable lids, soft seated needle valves & line pressure gauges.

The culmination of additional years of development has resulted in Mid-West’s latest product offering, the Model 845. This new model features all the benefits you’ve come to expect from our kits and is available in 5-valve (STOCK), 3-valve and 2-valve (ORDER ONLY) configurations. The Model 845 also comes with a new spacious carrying case with external fitting/tool compartments. The addition of the Model 845 to our product lineup truly allows Mid-West to offer “A Test Kit for Every Preference”!

Features

- Portable/removable from case.

- Improved case with storage compartments for fittings and tools.

- Room for additional accessories.

- Specially designed for testing backflow prevention assemblies with over 30 years of input from YOU the tester.

- Durable carrying case included.

All Test Kits Have: Soft Seated Needle Valves With Replaceable Seats, Durable Carrying Case, Laminated Test Procedures, Line Pressure Gauge, Adapter Fittings, In Line Hose Filters – Field Serviceable

Capable of performing all known test procedures including those recommended by ASSE, AWWA, CSA, FCCC & HR-USC, and NEWWA.

Flow Test Kits

Whether you are looking for a high accuracy portable test kit for flow and leak detection, or a more rugged medium accuracy test kit, Mid-West Instrument has designed and manufactures the right flow test kit for your budget and application.

Accuracy: This kit is equipped with a precise (±1% of full scale) accuracy differential pressure gauge.

Popular Applications:

(include but are not limited to)

- Measuring the pressure drop across various types of equipment i.e. filters

- Balancing HVAC systems

- Checking pump performance

- Orifice plates

- Checking calibration of transmitters

- Reading flow directly when ordered with a square root dial

Range: 0-80″ H2O thru 0-600″ H2O

Accuracy: This kit is equipped with a precise (±1% of full scale) accuracy differential pressure gauge.

Popular Applications: (include but are not limited to)

- Measuring the pressure drop across various types of equipment i.e. filters

- Balancing HVAC systems

- Checking pump performance

- Orifice plates, checking calibration of transmitters

- Reading flow directly when ordered with a square root dial

Range: 0-15 PSID thru 0-500 PSID

Accuracy: This kit is equipped with a precise (±1% of full scale) accuracy differential pressure gauge.

Popular Applications: (include but are not limited to)

- Measuring the pressure drop across various types of equipment i.e. filters

- Balancing HVAC systems

- Checking pump performance

- Orifice plates, checking the calibration of transmitters

- Reading flow directly when ordered with a square root dial.

Range: 0-5 PSID thru 0-100 PSID

Accuracy: This test kit is equipped with a ±3-2-3% of full-scale accuracy (ascending) piston type differential pressure gauge.

Popular applications: (include but are not limited to)

- Measuring pressure drop across various types of equipment

- Filters

- Checking pump performance

- Balancing valves

- Checking equipment for excessive pressure drop

- Leakage

Accuracy: This test kit is equipped with a ±3-2-3% of full-scale accuracy (ascending) diaphragm type differential pressure gauge. Ideally suited for applications where differential pressures of 0-5” to 0-400” H2O may be encountered.

Popular Applications:

- Balancing heating & cooling systems

- Checking pump performance

- Leakage

- Checking equipment for excessive pressure drop (i.e. filters, balancing valves, averaging pitot tubes, orfice plates, etc.)

- Dials may be for reading differential pressure, or reading flow directly, if ordered with a flow (square root) dial.

Range: 0-50″ H2O thru 0-100 PSI

Accuracy: This test kit is equipped with a ±3-2-3% of full-scale accuracy (ascending) diaphragm type differential pressure gauge.

Popular Applications: (include but are not limited to)

- Measuring pressure drop across various types of equipment

- Filters

- Checking pump performance

- Balancing valves

- Checking equipment for excessive pressure drop

- Leakage

Range: 0-50″ H2O thru 0-100 PSID

Accuracy: This kit is equipped with two differential pressure gauges with complimentary dials ranges, enabling it to cover broad range differential pressures and accuracies from ±5% to ± 3-2-3% full scale (ascending).

Primarily Use & Popular Applications: Primarily used for balancing HVAC systems it has numerous other applications which include but are not limited to, checking pump performance, checking pressure drop across filters, leakage, etc.

Range: 0-10″ H2O thru 0-100 PSID

Accuracy: This kit is equipped with two differential pressure gauges with complimentary dials ranges, enabling it to cover broad range differential pressures and accuracies of ± 3-2-3% full scale (ascending).

Applications: While primarily used for balancing HVAC systems it has numerous other applications which include but are not limited to, checking pump performance, checking pressure drop across filters, leakage, etc.

Backflow Services

Expert Service for Backflow Applications

Backflow testing and recertification for municipal and other governmental requirements are central product and service areas for us at Specialty Valve & Controls. We are a sales, service center, and stocking distributor for Mid West Instrument which is the leading manufacturer of backflow testing equipment.

For the past 30 years, Mid-West Instrument has been producing Quality Backflow Test Kits that have set the standard in the industry. Our Model 830 has been the benchmark of the industry for decades. Constant input from field testers led to refinements such as inline filters, laminated test procedures, removable lids, soft seated needle valves & line pressure gauges.

Repair & Re-Certification Price List for Mid-West Instrument Model 830, 835, 845, & Non-Mid-West Instrument Units

Note: Mid-West provides a 5-year warranty from date of manufacture. Filters must be in the unit when received or warranty will be void. Conbraco’s warranty is 1 year.

Services & Pricing

| UNIT RE-CERTIFICATION | Verify instrument is in calibration, affix calibration certification label, provide calibration certificate and issue test report with gauge reading. |

$99.00 |

| UNIT CALIBRATION | Minor repairs/cleaning to correct any minor problems found which limits ability to calibrate. | $49.00 |

|

STANDARD REPAIR |

Includes Re-certification. Requiring (any or all) cleaning, re-calibration, lens, fitting, and/or valve replacement, etc. | $184.00 |

| MAJOR REBUILD FOR 830/845 | Includes Re-certification. Standard repair plus diaphragm replacement. Includes diaphragm. | $284.00 |

|

Average turnaround is 1 working day for re-certification only. Standard and major repairs average 2-4 working days.

Please add $20.00 for return shipping and handling. Call 704-522-9873. |

||

Mid-West offers a 15% to 20% trade-in discount on Mid-West branded test kits.

Mid-West Instrument’s Scrap Value Guidelines:

If a test kit bearing the Mid-West Instrument brand name is deemed beyond useful repair the customer can trade in the un-repairable test kit and purchase a new replacement test kit at current list price, less a 20% scrap value discount. This policy does not apply to test kits manufactured by Mid-West that bear other brand names.

The kit must be turned in by its registered owner referenced with that serial number. The kit must be surrendered prior to the purchasing of a new Mid-West test kit.

Specialty Valve Scrap Value Guidelines on Non-Mid-West Kits:

If a test kit bearing a non-Mid-West brand name (i.e. Conbraco, Zurn, etc.) the customer can trade it in and purchase a new replacement Mid-West test kit at current list price, less a 15% scrap value discount.

The kit must be turned in by the registered owner referenced with that serial number. The kit must be surrendered prior to the purchasing of a new Mid-West test kit.

This Non-Mid-West trade in is a promotion of Specialty Valve & Controls not Mid-West.

Each new Mid-West test kit comes with a 5 Year Warranty and has a factory certification for the year.

Factory Authorized Stocking Distributors For 5 Years

Manufacturer hereby represents and warrants that all products sold shall be free from defects in workmanship and material for such products. Manufacturer does not make any other warranties and expressly disclaims all other warranties, expressed or implied, of any kind or nature, under any applicable law, including, without limitation, the uniform commercial code, as adopted in the state of Michigan. Without limiting the generality of the foregoing, manufacturer expressly disclaims any warranty of merchantability, and any warranty of suitability or fitness for any particular or intended purpose or use.

The sole and exclusive remedy shall be limited to replacement or repair of any product which has a defect in workmanship or material. In no event shall manufacturer be liable to any representative, distributor, customer, ultimate user or any other person or entity for any damages, costs, expenses or liabilities of any kind or nature, including, without limitation, direct damages, indirect damages, consequential damages, labor cost, and any expenses incurred by any distributor, customer, ultimate user or any other person or entity relating to the installation, use, repair or replacement of any product.

This product warranty and disclaimer shall apply to all sales of products. Printed circuit boards, switches, and other electrical components carry the above product warranty for a period of one year from the date of shipment.

Differential Pressure Gauges & Switches

Mid-West Instrument, located in Sterling Heights, MI is one of the leading designers and manufacturers of differential pressure gauges and switches in the U.S. The firm’s experienced engineers and technicians utilize the latest equipment for engineering, manufacturing, and testing the firm’s gauge and switch products.

Product Features:

- Dry Design, No Liquid Fill Required for Over-range Protection

- Glass Reinforced Thermoplastic Gauge Front Is Standard

- Weather Resistant & Corrosion Resistant Gauge Front

- ± 1/2% or ± 1% Full Scale Accuracy

- Six Inch Dial Standard

- 5 Year Warranty

Model 105 Bellows

The Model 105/106 bellows design provides a simple, compact, accurate, direct-acting, low range differential pressure indicator

Common Applications

- Pressurized Tank Level Monitoring

- Stationary Tanks- Horizontal or Vertical

- Tanker Transport

- Flow Indication

- Filter Monitoring for Gases

Product Features

- Over-Range Protection, High over Low and Low over High

- Micro Adjust Pointer

- Wide Selection of DP Ranges & Scales

- Bellows or Multiple Diaphragm Sensing Element

- Working Pressures up to 6000 PSIG (400 bar)

- Gauge Housings available in Aluminum, Brass, Carbon Steel and Stainless Steel 316/316L

- Wide Range of Elastomers

Product Features/Benefits

- Dry Design, No Liquid Fill Required for Over-range Protection

- Glass Reinforced Thermoplastic Gauge Front Is Standard

- Weather Resistant & Corrosion Resistant Gauge Front

- 270º Dial Arc

- Flow Scales Available

- 5-Year Warranty

Specifications

- Differential Pressure Range 0-10″ H2O to 0-79.9″ H2O (or Equivalent) Uni-Directional or Bi-Directional

- Accuracy ±1% F.S. Standard, ± 1/2% F.S. Optional

- Dial Size 6″ (Standard), 4-1/2″ (Optional)

- Working Pressure up to 6000 PSIG (400 bar)

- Material of Construction – Body Aluminum, Brass, Carbon Steel, 316/316L Stainless Steel

- Materials of Construction – Internals Copper Alloy or Stainless Steel

- Switch Options

- 1 or 2 Switches

- SPDT or DPDT Outputs

- 10 AMP @ 30 VDC, 120/240 VAC

- Adjustable from 5 to 95% F.S.

- Electrical Enclosures Weather-proof or Explosion-proof

Special Features

- Over-range Protection Full to Maximum Working Pressure

- Panel Mounting Standard, Front or Panel 6″ or 4-1/2″

- Pipe Mounting Kit Optional, 2″ U-Bolt

- Wall Mounting Optional – Flush Panel or Rear Bracket

- NACE Compliance Optional

The Mid-West Advantage

- 5 Year Warranty

- 30+ Years Hazardous Location product manufacturer.

- OEM capability

- Fast on-time Deliveries

- Friendly Customer Support

- Certified Quality System CSA B51-09 SAI GLOBAL

Overview

The body halves provide the pressure containment function. They also clamp the sensing element and over-pressure assembly between the halves, isolating the high side and low side pressures of the system. The high side body half also provides a mount for the torque tube assembly and the gauge front assembly.

The sensing element is exposed to the differential pressure and deflects in response to the differential pressure. This assembly incorporates a bidirectional relief valve which provides over-pressure protection in both directions. When over-pressured from the high side, the valve is opened by a mechanical stop as the sensing element deflects to its maximum travel. When over-pressured from the low side, the spring-loaded valve opens when the differential pressure exceeds its maximum rating. The opening of the valve in either direction equalizes the pressure and protects the unit.

A range spring is provided to adjust the spring rate of the system to suit the various differential pressure ranges of the instrument.

Operating & Installation Instructions | Locked Logic Installation | Installation Recommendations | Typical Manifold Installation

Model 106 Bellows

Common Applications

- Pressurized Tank Level Monitoring

- Stationary Tanks – Horizontal or Vertical

- Tanker Transport

- Flow Indication

- Filter Monitoring for Gases

Product Features

- Over-Range Protection, High over Low and Low over High

- Micro Adjust Pointer

- Wide Selection of DP Ranges & Scales

- Bellows or Multiple Diaphragm Sensing Element

- Working Pressures up to 6000 PSIG (400 bar)

- Gauge Housings available in Aluminum, Brass, Carbon Steel and Stainless Steel 316/316L

- Wide Range of Elastomers

Product Features/Benefits

- Dry Design, No Liquid Fill Required for Over-range Protection

- Glass Reinforced Thermoplastic Gauge Front Is Standard

- Weather Resistant & Corrosion Resistant Gauge Front

- 270º Dial Arc

- Flow Scales Available

- 5 Year Warranty

Specifications

- Differential Pressure Range 0-80″ H2O to 0-800″ H2O (or Equivalent) Uni-Directional or Bi-Directional

- Accuracy ±1% F.S. Standard, ± 1/2% F.S. Optional

- Dial Size 6″ (Standard), 4-1/2″ (Optional)

- Working Pressure up to 6000 PSIG (400 bar)

- Material of Construction – Body Aluminum, Brass, Carbon Steel, 316/316L Stainless Steel

- Materials of Construction – Internals Copper Alloy or Stainless Steel

- Locked Logic Switch Options (6″ Dial Only)

- 1 or 2 Switches

- SPDT or DPDT Outputs

- 10 AMP @ 30 VDC, 120/240 VAC

- Adjustable from 5 to 95% F.S.

- Snap Acting Switch Options (6″ Dial Only)

- 1 or 2 Switches

- SPDT Outputs

- 4 AMP @ 30 VDC

- 3 AMP @ 240 VAC

- 5 AMP @ 120 VAC

- Adjustable from 3% to 100% F.S.

- Electrical Enclosures Weather-proof or Explosion-proof

Special Features

- Over-range Protection Full to Maximum Working Pressure

- Panel Mounting Standard, Front or Panel 6″ or 4-1/2″

- Pipe Mounting Kit Optional, 2″ U-Bolt

- Wall Mounting Optional – Flush Panel or Rear Bracket

- NACE Compliance Optional

- Seismic Compliance Optional

The Mid-West Advantage

- 5 Year Warranty

- 30 + Years Hazardous Location product manufacturer.

- OEM capability

- Fast on-time Deliveries

- Friendly Customer Support

- Certified Quality SystemCSA B51-09 SAI GLOBAL

Installation & Operation:

Model 109 Bourdon Tube

Overview

The Model 109 encapsulated Bourdon tube design provides a simple, compact, and accurate differential pressure indicator.

Common Applications

- Pump Performance Testing

- Flow Indication

- Hydraulic Filter Monitoring

- Heat Exchanger Pressure

- Drop Monitoring

Product Features

- Wide DP Range from 0-15 PSID to

- 0-6000 PSID

- Bourdon Tube Sensing Element

- Working Pressures up to 6000 PSIG (400 bar)

- Over-Range Protection, High over Low and Low over High

- Gauge Housings Available in Aluminum, Brass, Carbon Steel and 316/316L Stainless Steel

- Wide Range of Elastomers

Product Features/Benefits

- Dry Design, No Liquid Fill Required for Over-range Protection

- Glass Reinforced Thermoplastic Gauge Front Is Standard

- Weather Resistant & Corrosion Resistant Gauge Front

- 270º Dial Arc

- Flow Scales Available

- 5 Year Warranty

Specifications

- Differential Pressure Range 0-15 PSID to 0-6000 PSID (or Equivalent) Uni-directional or Bi-directional

- Accuracy ±1% F.S. Standard, ± 1/2% F.S. Optional

- Dial Size 6″ (Standard), 4-1/2″ (Optional)

- Working Pressure up to 6000 PSIG (400 bar)

- Material of Construction – Body Aluminum, Brass, Carbon Steel, 316/316L Stainless Steel

- Materials of Construction – Internals Copper Alloy or Stainless Steel

- Switch Options

- 1 or 2 Switches

- SPDT or DPDT Outputs

- 10 AMP @ 30 VDC, 120/240 VAC

- Adjustable from 5 to 95% F.S.

- Electrical Enclosures Weather-proof or Explosion-proof

Special Features

- Over-range Protection – Full to Maximum Working Pressure

- Panel Mounting – Standard, Front or Panel 6″ or 4-1/2″

- Pipe Mounting Kit – Optional, 2″ U-Bolt

- Wall Mounting – Optional – Flush Panel or Rear Bracket

- NACE Compliance – Optional

- Seismic Compliance – Optional

The Mid-West Advantage

- 5 Year Warranty

- 30 + Years Hazardous Location product manufacturer.

- OEM capability

- Fast on-time Deliveries

- Friendly Customer Support

- Certified Quality SystemCSA B51-09 SAI GLOBAL

Detailed Description

The Model 109 is powered by a test quality Bourdon Tube Assembly. The assembly is encapsulated in a high pressure chamber that is fitted with a pressure connection to the inside of the Bourdon Tube and a second connection to the pressure chamber. The Model 109 indicates the difference between the pressure applied inside the Bourdon Tube and the pressure inside the chamber.

The pressure chamber for the assembly is small, close fitting and rugged. The volume displacement of the Bourdon Tube through the pressure range is near to zero (0.02 c.c.). The speed of response of the indicator to changes in differential pressure is instantaneous, even on low volume pressure systems. The low volume displacement is an important advantage for differential pressure leak detection, and when isolation diaphragms are required.

The Bourdon Tube Assembly is protected against over-range in either direction to the rated working pressure by a bi-directional relief valve. The output shaft of the gauge assembly is magnetically coupled through the solid wall of the pressure chamber to a sensitive jeweled pointer shaft in the dial housing outside the chamber. The magnetic coupling transmits the exact motion of the assembly to the pointer to give an accurate dial reading of the differential pressure.

Model 109 Bulletin | Electrical Description Bulletin

Installation & Operation

Model 116 Cryogenic

Common Applications:

- Pressurized Tank Level Monitoring

- Stationary Tanks- Horizontal or Vertical

- Tanker Transport

- Cryogenic/Liquefied Gas Applications

- Tank Application Data Sheet

Product Features:

- Drop in replacement for Barton and Prime Measurements

- Over-Range Protection, High over Low and Low over High

- Micro adjust pointer

- DP Ranges from 0-70″ H2O to 0-800″ H2O

- Tamper Proof, All adjustments require removal of bezel for access.

- Snap acting micro switch for alarm (optional)

- In house Oxygen Cleaning (optional)

- Private labeling (optional)

- Black ink on white dial or White ink on back dial

Product Features / Benefits:

- “Engineered Plastic” gauge front and optional stainless steel body bolts provide superior corrosion resistance in “over-the-road” trailers, outdoor or salt air environments

- Dry gauge design with no internal liquid fill

- Eliminates costly clean up from liquid fill leaking and fouling the tank and system

- No gauge damage/accuracy loss caused by liquid fill expansion/contraction when

- Exposed to temperature shocks in cryogenic applications

- Up to a 30 lb. (14 kg) weight savings on liquid Helium and Hydrogen

- Allows more products to be transported in mobile trailers

- Easier and less labor to panel mount

- Adaptable to a wide variety of mounting configurations

- Ability to create custom dials for horizontal and vertical tanks

- Warranty: One Year

Specifications:

- Accuracy: ±1% of Full Scale

- DP Range: 0-70″ H2O to 0-800″ H2O (175 mbar to 2.0 bar)

- Safe Working Pressure: 500 PSIG (Standard) 1000 PSIG (optional)

- Body Material: Brass

- Internals: 316 S.S. Convoluted Bellows

- Port: Dual Top and Bottom, 1/4″ FNPT connections with optional snubbers

- Vilton® Standard, other elastomers available

- 6″ Black Dial with White Lettering (White Dial with Black Lettering)

- Switch Options

- 1 Switch

- SPDT Outputs

- 4 Amp @ 30 VDC

- 3 Amp @ 240 VAC

- 5 Amp @ 120 VAC

- Adjustable from 3% to 100% F.S.

- Operating Temperature -20ºF to +185ºF

- Electrical Enclosures Weather-proof NEMA 4

Proof Pressure:

- Two times working pressure at ambient temperature

Static Pressure:

- 500 PSIG and 1000 PSIG Static Pressure

Temperature Limits:

- -40ºF (-40ºC) to 200ºF (93ºC)

Standards:

Model 116 Series Gauges either conform to and/or are designed to the requirements of the following standards;

- ASME B1.20.1

- ASME B40.100

- NEMA Std. No. 250

- UL Std. No. 50

- CSA-C22.2 No. 14

- SAE J514

The Mid-West Advantage:

- 1 Year Warranty

- 30 + Years Hazardous Location product manufacturer.

- OEM capability

- Fast on-time Deliveries

- Friendly Customer Support

- 3rd Party Certified Quality System

Model 115 & 116 Bulletin | Cryogenic Level Micro Switch | Over-Range Protection

Installation & Operation:

Model 115 Cryogenic

Common Applications:

- Pressurized Tank Level Monitoring

- Stationary Tanks- Horizontal or Vertical

- Tanker Transport

- Cryogenic/Liquefied Gas Applications

Product Features:

- Drop in replacement for Barton and Prime Measurements

- Over-Range Protection, High over Low and Low over High

- Micro adjust pointer

- DP Ranges from 0-10″ H2O to 0-69.9″ H2O

- Tamper Proof, All adjustments require removal of bezel for access.

- Snap acting micro switch for alarm (optional)

- In house Oxygen Cleaning (optional)

- Private labeling (optional)

- Black ink on white dial or white ink on black dial

Product Features / Benefits:

- “Engineered Plastic” gauge front and optional stainless steel body bolts provide superior corrosion resistance in “over-the-road” trailers, outdoor or salt air environments

- Dry gauge design with no internal liquid fill

- Eliminates costly clean up from liquid fill leaking and fouling the tank and system

- No gauge damage/accuracy loss caused by liquid fill expansion/contraction when

- exposed to temperature shocks in cryogenic applications

- Up to a 30lb. (14 kg) weight savings on liquid Helium and Hydrogen

- Allows more products to be transported in mobile trailers

- Easier and less labor to panel mount

- Adaptable to a wide variety of mounting configurations

- Ability to create custom dials for horizontal and vertical tanks

- Warranty: One Year

Specifications:

- Accuracy: ±1% of Full Scale

- DP Range: 0-10″ H2O to 0-69.9″ H2O (25 mbar to 175 mbar)

- Safe Working Pressure: 1500 PSIG

- Body Material: Brass

- Internals: 316 S.S. Welded Multiple Diaphragm

- Port: Dual Top and Bottom, 1/4″ FNPT connections with optional snubbers

- Vilton® Standard, other elastomers available

- 6″ Black Dial with White Lettering (White Dial with Black Lettering)

- Switch Options only available in ranges starting at 80″ H2O

Proof Pressure:

- Two times working pressure at ambient temperature

Static Pressure:

- 500 PSIG and 1000 PSIG Static Pressure

Temperature Limits:

- -40ºF (-40ºC) to 200ºF (93ºC)

Standards:

Model 115 Series Gauges either conform to and/or are designed to the requirements of the following standards;

- ASME B1.20.1

- ASME B40.100

- NEMA Std. No. 250

- UL Std. No. 50

- CSA-C22.2 No. 14

- SAE J514

The Mid-West Advantage:

- 1 Year Warranty

- 30 + Years Hazardous Location product manufacturer.

- OEM capability

- Fast on-time Deliveries

- Friendly Customer Support

- 3rd Party Certified Quality System

Model 115 & 116 Bulletin | Over-Range Protection | Tank Application Data Sheet | Cryogenic Level Micro Switch Information

Installation & Operation:

Operating & Installation Instructions | Switch Operating & Installation Instructions | Installation Recommendations | Typical Manifold Installation

Piston-Type Differential Pressure Gauges are available with one or two hermetically sealed reed switches. The switches are adjustable within a defined percentage of the full scale range of the gauge and are available in SPDT and SPST, normally open or normally closed configurations for various load/power ratings. The switches can be set to activate or deactivate on rising or falling pressure. Switches are “CE” marked per the EU low voltage directive.

Model 120 “Filter Minder”

Common Applications:

- Filter/Strainer Monitoring

- Compressed Air

- Hydraulic

- Refrigerant

- Pump Performance Testing

- Heat Exchanger Pressure Drop Monitoring

Product Features:

- DP Ranges from 0-5 PSID to 0-110 PSID

- Piston Sensing Element

- Working Pressures up to 6000 PSIG (400 bar)

- Over-Range Protection, High over Low and Low over High

- Gauge Housings available in Aluminum, Brass, 316/316L Stainless Steel, Aluminum Bronze and Monel

- Wide Range of Elastomers

Product Features/Benefits:

- Simple Rugged Designs

- Glass Reinforced Thermoplastic Gauge Front Is Standard

- Weather Resistant & Corrosion Resistant Gauge Front

- Shatter Resistant Lens

- 5-Year Warranty

Specifications:

- Differential Pressure Range 0-5 PSID to 0-110 PSID (0-0.35 to 0-7.0 bar)

- Available in a Variety of Equivalent Ranges & Scales

- Accuracy ±2%*

- Operating Temp -40ºF to +200ºF (-40ºC to +93ºC)

- Dial Size 2-1/2″ Round (Standard), 3-1/2″ Round (Optional), 4-1/2″ Round (Optional)

- Working Pressures up to 6000 PSIG

- Material of Construction of Body – Aluminum, 316/316L Stainless Steel, Aluminum Bronze and Monel

- Materials of Construction of Internals – 316 Stainless Steel (Standard) and Monel

- Switch Options

- SPDT 3W, 125 VAC/VDC, 0.25 amps

- SPDT 60W, 240 VAC/VDC, 1.0 amps

- SPST 60W, 240 VAC/VDC, 3.0 amps

- Electrical Enclosures Weather-Resistant, NEMA 4X or NEMA 7

- CE Marked in Accordance With Low Voltage Directive

- Hazardous Locations

- Div I

- Div II

Special Features:

- Over-range Protection Full to Maximum Working Pressure

- Panel Mounting Standard

- Pipe Mounting Kit Optional – 2″ U-Bolt

- Wall Mounting Optional – Rear Mount

- NACE Compliance Optional

- Seismic Compliance Contact Factory

The Mid-West Advantage:

- 5-Year Warranty

- 30 + Years Hazardous Location product manufacturer.

- OEM capability

- Fast on-time Deliveries

- Friendly Customer Support

- Certified Quality System

Model 121 “Filter Minder”

Common Applications

- Filter/Strainer Monitoring

- Compressed Air

- Hydraulic

- Refrigerant

- Pump Performance Testing

- Heat Exchanger Pressure Drop Monitoring

Product Features

- DP Ranges from 0-5 PSID to 0-110 PSID (0.35 to 7.0 bar)

- Piston Sensing Element

- Working Pressure up to 6000 PSIG (400 bar)

- Over-Range Protection, High over Low and Low over High

- Gauge Housings available in Aluminum, 316/316L Stainless Steel.

- Wide Range of Elastomers

Product Features/Benefits

- Simple Rugged Designs

- Glass Reinforced Thermoplastic Gauge Front Is Standard

- Weather Resistant & Corrosion Resistant Gauge Front

- Shatter Resistant Lens

- 5 Year Warranty

Specifications:

- Differential Pressure Range 0-5 PSID to 0-110 PSID (0-0.35 to 0-7.0 bar)

- Available in a Variety of Equivalent Ranges & Scales

- Accuracy ±2%*

- Operating Temp -40ºF to +200ºF (-40ºC to +93ºC)

- Dial Size 2-1/2″ Round (Standard), 3-1/2″ Round (Optional), 4-1/2″ Round (Optional)

- Working Pressure 6000 PSIG (400 bar)

- Material of Construction of Body – Aluminum, 316/316L Stainless Steel.

- Materials of Construction of Internals – 316 Stainless Steel (Standard)

- Switch Options

- SPDT 3W, 0.25 Amp, 125 VAC ( 15-95% F.S.) adjustability

- SPST 60W, 3.0 Amp, 240 VAC ( 20-95% F.S.) adjustability

- Electrical Enclosures Weather-Resistant, NEMA 4X, IP65

- Transmitter Options

Special Features:

- Over-range Protection Full to Maximum Working Pressure

- Panel Mounting Standard

- Pipe Mounting Kit Optional – 2″ U-Bolt

- Wall Mounting Optional – Rear Mount

- NACE Compliance Optional

- Seismic Compliance Contact Factory

- Typical Manifold Installation

The Mid-West Advantage:

- 5-Year Warranty

- 30+ Years Hazardous Location product manufacturer.

- OEM capability

- Fast on-time Deliveries

- Friendly Customer Support

- Certified Quality System

Operating & Installation Instructions | Installation Recommendations | Typical Manifold Installation

Model 122 “Filter Minder”

Common Applications

- Filter/Strainer Monitoring

- Compressed Air

- Hydraulic

- Refrigerant

- Pump Performance Testing

- Heat Exchanger Pressure

- Drop Monitoring

Product Features

- DP Ranges from 0-5 PSID to 0-110 PSID

- Piston Sensing Element

- 3000 PSIG Working Pressure (200 bar)

- Over-Range Protection, High over Low and Low over High

- Gauge Housings Aluminum with 316 Stainless Steel Internals

- 2-1/2”, 3-1/2”, or 4-1/2” Round Dial

- Wide Range of Elastomers

Product Features/Benefits

- Simple Rugged Designs

- Glass Reinforced Thermoplastic Gauge Front is Standard

- Weather Resistant & Corrosion Resistant Gauge Front

- Shatter Resistant Lens

- 5 Year Warranty

Specifications:

- Differential Pressure Range 0-5 PSID to 0-110 PSID (0-0.35 to 0-7.0 bar)

- Accuracy ±5% Full Scale

- Working Pressure 3,000 PSIG (200 bar)

- Operating Temp. -40º F to +200º F (-40ºC to +93ºC)

- Body Material: Aluminum

- Internal Materials: 316 Stainless Steel

- Switch Options

- SPDT 3W, 125 VAC/VDC, 0.25 amps

- SPDT 60W, 240 VAC/VDC, 1.0 amps

- SPST 60W, 240 VAC/VDC, 3.0 amps

- CE Marked in accordance with low voltage directive

- Switch Mounting: Clamp On, Stick On Flat Pack

- Process Connections: 1/4″ FNPT End Conn.

- Gauge Design: Magnetically Coupled Piston

- Base Dimensions 3.3H” x 1.97W” x 4.93L”

Special Features:

- Over-range Protection Full to Maximum Working Pressure

- Panel Mounting Standard

- Pipe Mounting Kit Optional – 2″ U-Bolt

- Wall Mounting Optional – Rear Mount

The Mid-West Advantage:

- 5 Year Warranty

- 30 + Years Hazardous Location product manufacturer.

- OEM capability

- Fast on-time Deliveries

- Friendly Customer Support

- Certified Quality System

Model 122 Bulletin

Installation & Operation:

Operating & Installation Instructions | Installation Recommendations | Typical Manifold Installation

Model 123 “Filter Minder”

Common Applications

- Filter/Strainer Monitoring

- Compressed Air

- Hydraulic

- Refrigerant

- Pump Performance Testing

- Heat Exchanger Pressure

- Drop Monitoring

Product Features

- DP Ranges from 0-150 PSID to 0-400 PSID

- Piston Sensing Element

- 5000 PSIG Working Pressure (340 bar)

- Over-Range Protection, High over Low and Low over High

- Material Construction: Aluminum, 316/316L Stainless Steel

- 2-1/2”, 3-1/2” or 4-1/2” dial

- Reverse Pressure Ports Available

Product Features/Benefits

- Simple Rugged Designs

- Glass Reinforced Thermoplastic Gauge Front Is Standard

- Weather Resistant & Corrosion Resistant Gauge Front

- Shatter Resistant Lens

- 5 Year Warranty

Specifications:

- Differential Pressure Range 0-150 PSID to 400 PSID (0-10.3 to 0-27.6 bar)

- Accuracy ±2%*

- Working Pressure 5000 PSIG (340 bar)

- Available in a Variety of Equivalent Ranges & Scales

- Dial Size 2-1/2″ Round (Standard), 4-1/2″ Round (Optional)

- Working Pressure 6000 PSIG

- Material of Construction of Body – Aluminum, 316/316L Stainless Steel, Aluminum, Bronze, Monel

- Materials of Construction of Internals – 316 Stainless Steel (Standard), Monel

- Switch Options

- SPDT 3W, 125 VAC/VDC, 0.25 amps

- SPDT 60W, 240 VAC/VDC, 1.0 amps

- SPST 60W, 240 VAC/VDC, 3.0 amps

- Electrical Enclosures Weather-Resistant, NEMA 4X

- CE Marked in Accordance With Low Voltage Directive

Special Features:

- Over-range Protection Full to Maximum Working Pressure

- Panel Mounting Standard

- Pipe Mounting Kit Optional – 2″ U-Bolt

- Wall Mounting Optional – Rear Mount

- NACE Compliance Optional

The Mid-West Advantage:

- 5 Year Warranty

- 30 + Years Hazardous Location product manufacturer.

- OEM capability

- Fast on-time Deliveries

- Friendly Customer Support

- Certified Quality System

Model 123 Bulletin

Installation & Operation:

Operating & Installation Instructions | Electric Operating & Installation Instructions | Installation Recommendations | Typical Manifold Installation

Model 124

High Working Pressure: 10,000 PSI

Common Applications

- Sub Sea / Deep Well

- High Pressure Filter/Strainer Monitoring

- Compressed Air

- Hydraulic

- Refrigerant

- Pump Performance Testing

- Heat Exchanger Pressure Drop Monitoring

Product Features

- DP Ranges from 0-5 PSID to 0-400 PSID

- Piston Sensing Element

- Working Pressure up to 10,000 PSIG (689 bar)

- Proof Pressure 20,000 PSIG

- Over-Range Protection, High over Low and Low over High

- Gauge Housing 316L Stainless Steel

- Wide Range of Elastomers

Product Features/Benefits

- Simple Rugged Designs

- Glass Reinforced Thermoplastic Gauge Front Is Standard

- Weather Resistant & Corrosion Resistant Gauge Front

- Shatter Resistant Lens

- 1 Year Warranty

Specifications:

- Differential Pressure Range 0-5 PSID to 0-400 PSID (0-0.35 to 0-27.6 bar)

- Available in a Variety of Equivalent Ranges & Scales

- Accuracy ±2%*

- Operating Temp -40ºF to +200ºF (-40ºC to +93ºC)

- Dial Size 2-1/2″ Round (Standard), 3-1/2″ Round (Optional), 4-1/2″ Round (Optional)

- Working Pressure 10,000 PSIG

- Material of Construction of Body – 316/316L Stainless Steel, adjusting Screws & end plugs

- Materials of Construction of Internals – 316 Stainless Steel

- Switch Options

- SPDT 3W, 125 VAC/VDC, 0.25 amps

- SPDT 60W, 240 VAC/VDC, 1.0 amps

- SPST 60W, 240 VAC/VDC, 3.0 amps

- Electrical Enclosures Weather-Resistant, NEMA 4X

- CE Marked in Accordance With Low Voltage Directive

- Transmitter Options

Special Features:

- Over-range Protection Full to Maximum Working Pressure

- Panel Mounting Standard

- Pipe Mounting Kit Optional – 2″ U-Bolt

- Wall Mounting Optional – Rear Mount

- NACE Compliance Optional

The Mid-West Advantage:

- 5 Year Warranty

- 30 + Years Hazardous Location product manufacturer.

- OEM capability

- Fast on-time Deliveries

- Friendly Customer Support

- Certified Quality System

Model 124 Bulletin

Installation & Operation:

Operating & Installation Instructions | Electric Operating & Installation Instructions | Installation Recommendations | Typical Manifold Installation

Standard configuration can be customized and modified to suit a customer’s need for easy installation or retrofit. Differential Pressure is sensed by the movement of an elastomer diaphragm against a precision calibrated range spring. The change in position of the diaphragm in response to the change in Differential Pressure moves an internal magnet. This magnet, in turn, causes a rotary magnet external to the gauge body to rotate. This rotary magnet has a pointer attached which indicates the differential pressure on the dial.

All Mid-West Diaphragm-type Differential Pressure Gauges can be configured for use in hazardous locations.

Model 130 “Delta Gauge”

Common Applications

- Tank Level Monitoring

- Horizontal or Vertical

- Flow Indication/Balancing

- Filter Monitoring for Gases

- Water Treatment Applications

- Vacuum Application

Product Features

- Wide Selection of DP Ranges & Scales

- Elastomer Diaphragm Sensing Element, No Cross Port Leakage

- Up to 500 PSIG Working Pressure (34 bar)

- Over-Range Protection, High over Low and Low over High

- Gauge Housings available in Aluminum, Brass, 316/316L Stainless Steel and Polysulfone Thermoplastic

- Wide Range of elastomers

Product Features/Benefits

- Simple Rugged Designs

- Glass Reinforced Thermoplastic Gauge Front Is Standard

- Weather Resistant & Corrosion Resistant Gauge Front

- 5 Year Warranty

Specifications:

- Differential Pressure Range – 0-5″ H2O to 0-400″ H2O

- Available in a Variety of Equivalent Ranges and/or Flow Scales (square root)

- Accuracy – ±2%* OR ±5% of Full Scale

- Dial Size – 4-1/2″ Round (Standard)

- Working Pressure

- Engineered Thermo Plastic – 300 PSIG (20 bar)

- Metal – 500 PSIG (34 bar)

- Material of Construction – Body: Plastic, Aluminum, Brass 316/316L S.S. or Hastelloy C

- Materials of Construction – Internals: 316 S.S. or Hasteloy C and Elastomer Diaphragm

- Switch Options

- SPDT 3W, 125 VAC/VDC, 0.25 AMPs (metal body only)

- Electrical Enclosures – Weather-resistant, Weather-proof, NEMA 4X and NEMA 7

- Hazardous Location

Special Features:

- Over-range Protection – Full to Maximum Working Pressure

- Panel Mounting – Standard

- Pipe Mounting Kit – Optional – 2″ U-Bolt

- Wall Mounting – Optional – Rear Mount

- NACE Compliance – Optional

The Mid-West Advantage:

- 5 Year Warranty

- 30 + Years Hazardous Location product manufacturer.

- OEM capability

- Fast on-time Deliveries

- Friendly Customer Support

- Certified Quality System

Model 130 BulletinInstallation & Operation:

Operating & Installation Instructions | Electric Operating & Installation Instructions | Installation Recommendations | Typical Manifold Installation

Model 140 Delta Meter ®

Common Applications

- Filter/Strainer Monitoring

- Compressed Air, Hydraulic, Refrigerant

- Pump Performance Testing

- Heat Exchanger Pressure Drop Monitoring

- Water Treatment Applications

- Tank Level Monitoring Horizontal or Vertical

- Flow Monitoring & Balancing

Product Features

- DP Ranges from 0-25 PSID to 0-100 PSID

- Elastomer Diaphragm Sensing Element,

- No Cross Port Leakage

- Up to 3000 PSIG Working Pressure (200 bar)

- Over-Range Protection,

- High over Low and Low over High

- Gauge Housings available in Aluminum, Brass, 316/316L Stainless Steel and Acetal Plastic

- Wide Range of Elastomers

Product Features/Benefits

- Simple Rugged Designs

- Glass Reinforced Thermoplastic Gauge Front Is Standard

- Weather Resistant & Corrosion Resistant Gauge Front

- 5 Year Warranty

Specifications:

- DP Ranges from 0-25 PSID to 0-100 PSID

- Available in a Variety of Equivalent Ranges and/or Flow Scales (Square Root)

- Accuracy ±2%* or ±5% of Full Scale

- Dial Size 2-1/2″ Rd. (Standard)

- 4-1/2″ Rd. (Optional)

- Working Pressure Alum and S.S. – 3000 P.S.I.G. Brass – 1500 PSIG

- Material of Construction – Body: Aluminum, Brass, or 316 Stainless Steel

- Materials of Construction – Internals: 316 Stainless Steel and Elastomer Diaphragm

- Switch Options (Terminal Strip Interface)

- 1 or 2 – SPDT 3W, 125 VAC/VDC, 0.25 amps

- 1 or 2 – SPST (Normally Open) 25W, 240 VAC/VDC, 0.5 amps

- Electrical Enclosures NEMA 4X and NEMA 7

- CE Marked in Accordance With Low Voltage Directive

- Hazardous Locations

- Div I

- Div II

- Transmitter Options

Special Features:

- Over-range Protection Full to Maximum Working Pressure

- Panel Mounting Standard, Front or Rear Panel

- Pipe Mounting Kit Optional – 2″ U-Bolt

- Wall Mounting Optional – Rear Mount

- NACE Compliance Optional

The Mid-West Advantage:

- 5 Year Warranty

- 30 + Years Hazardous Location product manufacturer.

- OEM capability

- Fast on-time Deliveries

- Friendly Customer Support

- Certified Quality System

Model 140 Delta Meter BulletinInstallation & Operation:

Operating & Installation Instructions | Electric Operating & Installation Instructions | Installation Recommendations | Typical Manifold Installation

Model 142 Delta Meter ®

Common Applications

- Filter/Strainer Monitoring

- Compressed Air, Hydraulic, Refrigerant

- Pump Performance Testing

- Heat Exchanger Pressure Drop Monitoring

- Water Treatment Applications

- Tank Level Monitoring Horizontal or Vertical

- Flow Monitoring & Balancing

- Vacuum Application

Product Features

- DP Ranges from 0-20” WC to 0-25 PSID

- Elastomer Diaphragm Sensing Element, No Cross Port Leakage

- Up to 3000 PSIG Working Pressure (200 bar)

- Over-Range Protection, High over Low and Low over High

- Gauge Housings available in Aluminum, Brass, 316/316L Stainless Steel and Acetal Plastic

- Wide Range of Elastomers

Product Features/Benefits

- Simple Rugged Designs

- Glass Reinforced Thermoplastic Gauge Front Is Standard

- Weather Resistant & Corrosion Resistant Gauge Front

- 5 Year Warranty

Specifications:

- Differential Pressure Range 0-20″ H2O to 0-25 PSID

- Available in a Variety of Equivalent Ranges and/or Flow Scales (Square Root)

- Accuracy ±2%* of Full Scale

- Dial Size 2-1/2″ Rd. (Standard)

- 4-1/2″ Rd. (Optional)

- Working Pressure Alum and S.S. – 3000 P.S.I.G. Brass – 1500 PSIG

- Material of Construction – Body Aluminum, Brass, or 316 Stainless Steel

- Materials of Construction – Internals 316 Stainless Steel and Elastomer Diaphragm

- Switch Options (Terminal Strip Interface)

- 1 or 2 – SPDT 3W, 125 VAC/VDC, 0.25 amps

- 1 or 2 – SPST (Normally Open) 25W, 240 VAC/VDC, 0.5 amps

- Electrical Enclosures NEMA 4X and NEMA 7

- CE Marked in Accordance With Low Voltage Directive

- Hazardous Locations

- Transmitter Options

Special Features:

- Over-range Protection Full to Maximum Working Pressure

- Panel Mounting Standard, Front or Rear Panel

- Pipe Mounting Kit Optional – 2″ U-Bolt

- Wall Mounting Optional – Rear Mount

- NACE Compliance Optional

The Mid-West Advantage:

- 5 Year Warranty

- 30 + Years Hazardous Location product manufacturer.

- OEM capability

- Fast on-time Deliveries

- Friendly Customer Support

- Certified Quality System

Model 142 Delta Meter BulletinInstallation & Operation:

Operating & Installation Instructions | Electric Operating & Installation Instructions | Installation Recommendations | Typical Manifold Installation

Model 522

Common Applications

- Filter/Strainer Monitoring

- Compressed Air, Hydraulic, Refrigerant

- Pump Performance Testing

- Heat Exchanger Pressure Drop Monitoring

- Water Treatment Applications

Product Features

- DP Ranges from 0-5 PSD to 0-50 PSID

- Elastomer Diaphragm Sensing Element

- Up to 1000 PSIG Working Pressure (69 bar)

- Maximum DP Pressure: (High to Low) 200 PSID

- Gauge Housings available in Aluminum, 316/316L Stainless Steel and Acetal Plastic

- Buna-N and Viton Elastomers

Product Features/Benefits

Model 522 Differential Pressure Gauge & Switch is a compact, weather resistant gauge for challenging DP Applications and installations. It is suitable for use in outdoor and “Hose Down” applications. The Rolling Diaphragm Sensing Element isolates the high and low side.

- Simple Rugged Designs

- Glass Reinforced Thermoplastic Gauge Front Is Standard

- Weather Resistant & Corrosion Resistant Gauge Front

- 5 Year Warranty

Specifications:

- Differential Pressure Range 0-5 PSID to 0-50 PSID

- Available in Dual Scale PSID/bar and PSID/kPa

- Accuracy ±5% of Full Scale (Acending)

- Dial Size 2-1/2″ Rd. (Standard)

- Working Pressure:

- 1000 PSI (69 bar) for Aluminum & Stainless Steel

- 500 PSI (34.5 bar) for Acetal

- Proof Pressure:

- 2000 PSI (138 bar) for Aluminum & Stainless Steel

- 1000 PSI (69 bar) for Acetal

- Material of Construction – Body Aluminum, 316 Stainless Steel, or Acetal

- Maximum Differential Pressure:

- (Hi to Low) – 200 PSID (13.8 bar)

- Materials of Construction – Internals 316 Stainless Steel and Elastomer Diaphragm

- Switch Option

- DIN 43650/IP65/NEMA 4X Plug-in Connector

- 1 – SPST 60W, 3 amps, 240 VAC/VDC

- CE Marked in Accordance With Low Voltage Directive

Special Features:

- Standard: Panel Mounting, Front or Rear Panel

- Optional: (2) 10-32 Mounting Holes on back of gauge body – 1.75″ Apart x .330″ Depth

The Mid-West Advantage:

- 5 Year Warranty

- 30 + Years Hazardous Location product manufacturer.

- OEM capability

- Fast on-time Deliveries

- Friendly Customer Support

- Certified Quality System

Model 522 BulletinInstallation & Operation:

Operating & Installation Instructions | Installation Recommendations | Typical Manifold Installation

Models 700, 710, 715

Mid-West Instrument Model 700 Wet/Wet Differential Pressure Transmitter utilizes a piezoresistive differential pressure sensor sensing element with stainless steel isolated diaphragm. Silicon oil is filled in between die and two diaphragms. The measured differential pressure is transmitted onto the die through the diaphragm and silicon oil. The signal output generated by the piezoresistive bridge sensor is amplified into a useable voltage or 4-20 mA output as specified by customer. 1 Year Limited Warranty

Common Applications Monitor Differential Pressure Across:

- Filters

- Local Flow Indication

- Factory Pneumatic Air

- Heat Exchangers

- Strainers, Pumps

- Pitot Tubes

- Level Applications

Product Features

- Available Ranges:

- 0-5 PSID (0.35 bar) to 0-300 PSID (0-20.0 bar)

- Use with Liquid or Gas media compatible with material of construction

- Full stainless steel construction, compact size, easy installation

- Laser welded, fully-sealed construction: NEMA 4X (IP65)

- Utilizes Piezoresistive Differential Pressure Sensor Isolated Diaphragm

- Zero Adjust / Potentiometer ±5%

- Span Adjustable / Potentiometer ±5%

- CE Certified to EMI / EMC Directive

- LCD or LED display available upon request

- (Available with DIN Connector & 4-20mA Output only, 2-Wire 20-28 VDC)

- Maximum Overpressure:

- (+) Hi-Side equals 2 times specified DP range

- Maximum Overpressure:

- (-) Low-Side is equal to specified DP range

- Maximum Static Pressure 2,900 PSI

- Operating temperature limits – 14° F to 175° F.

- Storage temperature is -40° F to 200° F

- Sensor is temperature compensated from 32° F to 122° F

- Model 700 is Manufactured in China

It is recommended to install a 3 valve manifold between point of measurement and the transmitter.

Materials Construction

- Pressure Port & Housing: 321 Stainless Steel

- Diaphragm: 316L Stainless Steel

- O-Ring: Viton

- Standard Process Connections: ¼ ” Female BSPP

- (¼” BSPP x ¼” FNPT & ¼” BSPP x ½” FNPT S.S. Adapters Available)

- Fill liquid: Silicon Oil

Available Electrical Specifications:

- Power Supply: 2-Wire 15~28 VDC

- 3-Wire 15~28 VDC

- Output Signals: 2-Wire 4~20mADC,

- 3-Wire, 0~5VDC, 1~5VDC, 0~5VDC

- 0~10VDC, 0-10mADC and 0-20m ADC

- Electrical Connections: Din Plug 43650 or 1.5m 4-pin cable

- Response Time: (10%~90%) <=1ms

- Insulation Resistance 100MΩ, 50VDC

- CE Marked in Accordance With EMC Directive

Model 700 BulletinInstallation & Operation:

Operating & Installation Instructions

Mid-West Instrument has been designing and manufacturing indicating differential pressure switches for use in Hazardous Locations for over 30 years. Their products carry CSA, UL, and or ATEX certifications that apply to the entire assembly as mandated by the applicable Hazardous Locations Standards. In order to mark their product with the CSA & UL marks, Mid-West Instrument is subject to unannounced visits by personnel from each certification lab 4 times per year. In addition, for the ATEX certification, they are subject to a comprehensive audit from a Notified Body representative once every year.

Model 120 – Explosion Proof

Functions and Applications

The Model 120 piston style Differential Pressure Switch is CSA Certified to both the Canadian and U.S. Standards and U.L. Listed to the U.S. Standards. The entire assembly is Certified for use in Class I, Division 1, Groups C, D; Class II, Division 1, Groups E, F, & G Hazardous locations. The entire gauge and the switch is enclosed in a rugged flameproof enclosure. The use of reed switch technology eliminates the need for an additional explosion-proof seal fitting within 18” of the enclosure.

The Entire Assembly is Certified for Hazardous Locations

Specifications:

Certifications: CSA Certified, UL Listed, Class I, Division 1, Groups C, D;

Class II, Division 1, Groups E,F, & G.

Switch Option:

- Set Point Accuracy: 2%*

- Interface: 1/2” Conduit Entry with Color Coded 24”, 18 Awg. Flying Leads

- Enclosure: NEMA 7 (Flame-proof), NEMA 4X optional (In addition to NEMA 7)

- Switch Adjust: External Access to switch adjust internal to enclosure

- Input Power: None. (Switches do not need input power to operate)

Body:

- Working Pressure: 5000 PSIG (345 bar)

- Differential Over-range: 5000 PSID (345 bar)

- Range: 0-5 PSID (0-0.35 bar) to 0-100 PSID (0-7 bar)

- Process Connections: 1/4” MNPT Bottom

- Materials: AL, 316 / 316L SS, Brass

Indicator:

- Accuracy: 2%*

- Dial Size: 2 1/2” (Standard), 3 1/2”, or 4 1/2” None (Switch Only)

- Scales: Uni-directional , Bi-Directional

* ASME B40.100 Grade B

The Mid-West Advantage:

- 5 Year Warranty

- 30 + Years Hazardous Location product manufacturer.

- OEM capability

- Fast on-time Deliveries

- Friendly Customer Support

- Certified Quality System

Model 120 BulletinInstallation & Operation:

Operating & Installation Instructions | Electric Operating & Installation Instructions | Installation Recommendations | Typical Manifold Installation

Model 130 – Explosion Proof

Functions and Applications

The Model 130 diaphragm isolated Differential Pressure Switch is CSA Certified to both the Canadian and U.S. Standards and U.L. Listed to the U.S. Standards. The entire assembly is Certified for use in Class I, Division 1, Groups C, D; Class II, Division 1, Groups E, F, & G Hazardous locations. The entire gauge and the switch is enclosed in a rugged flameproof enclosure. The use of reed switch technology eliminates the need for an additional explosion-proof seal fitting within 18″ of the enclosure.

Certifications:

- CSA Certified, UL Listed, Class I, Division 1, Groups C, D;

- Class II, Division 1, Groups E,F, & G.

Switch Options:

- Set Point Accuracy: 2%*

- Interface: 1/2” Conduit Entry with Color Coded 24”, 18 Awg. Flying Leads

- Enclosure: NEMA 7 (Flame-proof), NEMA 4X optional (In addition to NEMA 7)

- Switch Adjust: External Access to switch adjust internal to enclosure

- Input Power: None. (Switches do not need input power to operate)

Body:

- Working Pressure: 500 PSIG (34.5 bar)

- Differential Over-range: 500 PSID (34.5 bar)

- Range: 0-5” H2O to 0 – 400” H2O

- High Side to Low side Isolation: Yes (Diaphragm Style)

- Process Connections: 1/4” MNPT Bottom

- Materials: AL, 316 / 316L SS, Brass, Hastelloy

Indicator:

- Accuracy: 2%*

- Dial Size: None (Switch Only), 3 1/2”, or 4 1/2”

- Readings: Uni-directional

The Mid-West Advantage:

- 5 Year Warranty

- 30 + Years Hazardous Location product manufacturer.

- OEM capability

- Fast on-time Deliveries

- Friendly Customer Support

- Certified Quality System

Model 130 BulletinInstallation & Operation:

Operating & Installation Instructions | Electric Operating & Installation Instructions | Installation Recommendations | Typical Manifold Installation

Model 140 – Explosion Proof

Common Applications

- Filter/Strainer Monitoring

- Compressed Air, Hydraulic, Refrigerant

- Pump Performance Testing

- Heat Exchanger Pressure Drop Monitoring

- Water Treatment Applications

- Tank Level Monitoring

- Horizontal or Vertical

Product Features

- DP Ranges from 0-25 PSID to 0-100 PSID

- Elastomer Diaphragm Sensing Element, No Cross Port Leakage

- Up to 3000 PSIG Working Pressure (200 bar)

- Over-Range Protection, High over Low and Low over High

- Gauge Bodies Available in Aluminum, Brass, Stainless Steel

- Wide Range of Elastomers

Certifications:

- CSA Certified, UL Listed, Class I, Division 1, Groups C, D;

- Class II, Division 1, Groups E,F, & G.

Switch Options:

- Set Point Accuracy: 2%

- Interface: 1/2” Conduit Entry with Color Coded 24”, 18 Awg. Flying Leads

- Enclosure: Aluminum NEMA 7 (Flame-proof), NEMA 4X optional (In addition to NEMA 7)

- Switch Adjust: External Access to switch adjust internal to enclosure

- Input Power: None. (Switches do not need input power to operate)

Body:

- Working Pressure: 3000 P.S.I.G. (200 bar)

- Differential Over-range: 3000 PSID (200 bar)

- Range: 0-25 PSID to 0- 100 PSID (0 – 1.7 bar to 0 – 7 bar)

- High Side to Low side Isolation: Isolated (Diaphragm Style)

- Process Connections: 1/4” MNPT Bottom

- Materials: AL, 316 / 316L SS, Brass

Indicator:

- Accuracy: 2%

- Dial Size: None (Switch Only), 2 1/2” (Standard), 3 1/2”, or 4 1/2”

- Readings: Uni-directional

The Mid-West Advantage:

- 5 Year Warranty

- 30 + Years Hazardous Location product manufacturer.

- OEM capability

- Fast on-time Deliveries

- Friendly Customer Support

- Certified Quality System

Model 140 Bulletin | Over Range Protection

Installation & Operation:

Operating & Installation Instructions | Electric Operating & Installation Instructions | Installation Recommendations | Typical Manifold Installation

Model 220 – Explosion Proof

The Model 220 carries global certifications from CSA, UL, and ATEX. The piston style Differential Pressure Switch is CSA Certified to both the Canadian and U.S. Standards and U.L. Listed to the U.S. Standards. Certified to ATEX directive Ex d, IIB + H2 with an IP65 rating.

Mid-West Instrument’s new Hazardous Locations “Delta P” switches are provided with a field wire-able terminal strip. The terminal strip eliminates the need to add a costly explosion-proof junction box near the switch. Multiple outputs are available ranging from low power reed switches to higher load switching relay outputs.

Features and Benefits

A competitively priced Indicating Differential Pressure Switch for use in measuring the pressure drop across filters, strainers, separators, valves, and pumps in Hazardous Locations.

- Simple, Rugged, Compact Design

- Working Pressure 3000 PSIG (200 bar)

- Over-range Protection to Maximum Pressure

- Captive Cover Screws

- The Entire Assembly is Certified for Hazardous Locations

Certifications:

- CSA Certified, UL Listed, Class I, Division 1, Groups B, C, D;

- Class II, Division 1, Groups E,F, & G.

- ATEX Certified, Ex d IIB + H2 II 2GD IP65

Switch Options:

- Set Point Accuracy: 2%*

- Interface: 1/2” Conduit / Cable Entry with 16 Position Terminal Strip

- Enclosure: NEMA 7 / Ex “d” (Flame-proof), IP65 Weatherproof rating

- Switch Adjust: Internal to the Enclosure

- Input Power: None. (For Reed switch Outputs) ; Required for Relay Output

Body:

- Working Pressure: 4000 PSIG (Division Classification) / 3000 PSIG (ATEX)

- Differential Over-range: Same as Working Pressure

- Range: 0-5 PSID (0-0.35 bar) to 0 -100 PSID (0-7 bar)

- Process Connections: 1/4” FNPT End Connected (Standard)

- Materials: 316 / 316L Stainless Steel

Indicator:

- Accuracy: 2%*

- Dial Size: 4 1/2” Standard None (Switch Only)

The Mid-West Advantage:

- 5 Year Warranty

- 30 + Years Hazardous Location product manufacturer.

- OEM capability

- Fast on-time Deliveries

- Friendly Customer Support

- Certified Quality System

Model 220 Bulletin

Installation & Operation:

Division 1 Electrical Operating & Installation Instructions | ATEX Electrical Operating & Installation Instructions | Installation Recommendations | Typical Manifold Installation

Model 240 – Explosion Proof

The Model 240 carries global certifications from CSA, UL, and ATEX. The diaphragm isolated Differential Pressure Switch is CSA Certified to both the Canadian and U.S. Standards and U.L. Listed to the U.S. Standards. In addition, it is certified to the ATEX directive Ex d, IIB + H2 with an IP 65 rating.

Mid-West Instrument’s new Hazardous Locations “Delta P” switches are provided with a field wireable terminal strip. The terminal strip eliminates the need to add a costly explosion-proof junction box near the switch. Multiple outputs are available ranging from low power reed switches to higher load switching relay outputs.

Features and Benefits

A competitively priced Indicating Differential Pressure Switch for use in measuring the pressure drop across filters, strainers, separators, valves, and pumps in Hazardous Locations.

- Total Separation of High and Low Pressures Sides

- Simple, Rugged, Compact Design

- Working Pressure 1500 PSIG (103 bar)

- Over-range Protection to Maximum Presssure

- Captive Cover Screws

- The Entire Assembly is Certified for Hazardous Locations

Certifications:

- CSA Certified, UL Listed, Class I, Division 1, Groups B, C, D;

- Class II, Division 1, Groups E,F, & G.

- ATEX Certified, Ex d IIB + H2 Ex II 2GD IP65

Switch Options:

- Set Point Accuracy: 2%*

- Interface: 1/2” Conduit / Cable Entry with 16 Position Terminal Strip

- Enclosure: NEMA 7 / Ex “d” (Flame-proof), IP65 Weatherproof rating

- Switch Adjust: Internal to the Enclosure

- Input Power: None. (For Reed switch Outputs) ; Required for Relay Output

Body:

- Working Pressure: 1500 PSIG (100 bar)

- Differential Over-range: Same as Working Pressure

- Range: 0-20″ H2O (0-50 mbar) to 0-100 PSID (0-7 bar)

- High Side to Low side Isolation: Isolated (Diaphragm Style)

- Process Connections: 1/4” FNPT End Connected (Standard)

- Materials: AL, 316 / 316L SS,

Indicator:

- Accuracy: 2%*

- Dial Size: 4 1/2” Standard None (Switch Only)

The Mid-West Advantage:

- 5 Year Warranty

- 30 + Years Hazardous Location product manufacturer.

- OEM capability

- Fast on-time Deliveries

- Friendly Customer Support

- Certified Quality System

Model 240 Bulletin

Installation & Operation:

ATEX Electrical Operating & Installation Instructions | Division 1 Electrical Operating & Installation Instructions | Transmitter Electric Operating & Installation Instructions | Installation Recommendations | Typical Manifold Installation

Model 120 – Division 2

Functions and Applications

The Division 2 rated product is a lower cost alternative when compared to the Explosion-Proof designs that are often used in Division 2 applications. Mid-West Instrument’s Model 120 is CSA Certified to both the Canadian and U.S. standards and U.L. Listed to the U.S. Standards. In addition the Model 120 indicating differential pressure switch is CE marked to the Low Voltage Directive.

Mid-West Instrument’s “Delta P” switches utilize reed switch technology. Reed switches can provide switching control from low power loads (PLC’s) to small inductive loads such as relays & small solenoids. With proper switch protection, over 1,000,000 cycles can be realized.

Specifications:

- Certifications: CSA Certified, UL Listed, Class I, Division 2, Groups A, B, C, D;

- Class II, Division 2, Groups F & G.

Switch Options:

- Set Point Accuracy: 2%*

- Interface: 1/2″ Conduit Entry with Color Coded  24″, 18 Awg. Flying Leads

- Enclosure: NEMA 4X / Type 4 switch enclosure classification.

- Switch Adjust: External Access

- Input Power: None. (Switches do not need input power to operate)

Body:

- Working Pressure: 5000 PSIG (345 bar)

- Differential Over-range: 5000 PSID (345 bar)

- Range: 0-5 PSID (0-0.35 bar) to 0-100 PSID (0-7 bar)

- Process Connections: 1/4” FNPT Back (Standard)

- Materials: AL, 316 / 316L SS, Brass

Indicator:

- Accuracy: 2%*

- Dial Size:Â None (Switch Only), 2 1/2″ (Standard), 3 1/2″, or 4 1/2″

- Scales: Uni-directional , Bi-Directional

The Mid-West Advantage:

- 5 Year Warranty

- 30 + Years Hazardous Location product manufacturer.

- OEM capability

- Fast on-time Deliveries

- Friendly Customer Support

- Certified Quality System

Model 120 Bulletin

Installation & Operation:

Operating & Installation Instructions | Electrical Operating & Installation Instructions | Installation Recommendations | Typical Manifold Installation

Model 140/142 – Division 2

Functions and Applications:

The Division 2 rated product is a lower cost alternative when compared to the Explosion-Proof designs that are often used in Division 2 applications. Mid-West Instrument’s Models 140/142 are CSA Certified to both the Canadian and U.S. standards and U.L. Listed to the U.S. Standards. In addition the Model 140 indicating differential pressure switch is CE marked to the Low Voltage Directive.

Mid-West Instrument’s “Delta P” switches utilize reed switch technology. Reed switches can provide switching control from low power loads (PLC’s) to small inductive loads such as relays & small solenoids. With proper switch protection, over 1,000,000 cycles can be realized.

Product Features

- DP Ranges from 0-20″ WC to 0-100 PSID

- Elastomer Diaphragm Sensing Element, No Cross Port Leakage

- Up to 3000 PSIG Working Pressure (200 bar)

- Over-Range Protection, High over Low and Low over High

- Gauge Housings Evailable in Aluminum, Brass, Stainless Steel and Acetal Plastic

- Wide Range of Elastomers

Certifications:

- CSA Certified, UL Listed, Class I, Division 2, Groups A, B, C, D;

- Class II, Division 2, Groups F & G.

Switch Options:

- Set Point Accuracy: 2%

- Interface: 1/2” Conduit Entry with 7 Position Terminal Strip

- Enclosure: NEMA 4X / Type 4 switch enclosure classification.

- Switch Adjust: External Access

- Input Power: None. (Switches do not need input power to operate)

Body:

- Working Pressure: 140 – 3000 P.S.I.G. (200 bar); 142 – 1500 (100 bar)

- Differential Over-range: 140 – 3000 PSID (200 bar); 142 – 1500 PSID (100 bar)

- Range: 0-20″ H2O to 0 -100 PSID (0-50 mbar to 0-7 bar)

- High Side to Low side Isolation: Isolated (Diaphragm Style)

- Process Connections: 1/4” FNPT Back (Standard)

- Materials: AL, 316 / 316L SS, Brass

Indicator:

- Accuracy: 2%

- Dial Size: None (Switch Only), 2 1/2” (Standard), 3 1/2”, or 4 1/2”

- Readings: Uni-directional , Bi-Directional

The Mid-West Advantage:

- 5 Year Warranty

- 30 + Years Hazardous Location product manufacturer.

- OEM capability

- Fast on-time Deliveries

- Friendly Customer Support

- Certified Quality System

Model 140 Bulletin | Model 142 Bulletin

Installation & Operation:

Model 140 Operating & Installation Instructions | Model 140 Electric Operating & Installation Instructions | Model 142 Operating & Installation Instructions | Model 142 Electric Operating & Installation Instructions | Installation Recommendations | Typical Manifold Installation

Model 220 – Division 2

Functions and Applications

The Model 220 classified for Division 2 locations provides another alternative to the installer that does not like additional junction boxes which are required for flying lead interfaces.

The piston style Model 220 configured for the Division 2 classification is CSA Certified to both the Canadian and U.S. Standards and U.L. Listed to the U.S. Standards. It also has a NEMA 4X (Type 4) weatherproof classification.

Mid-West Instrument’s new Hazardous Locations “Delta P” switches are provided with a field wireable terminal strip. Just loosen the “captive” screws & remove the cover to access the terminal strip. The terminal strip eliminates the need to add an additional junction box near the switch. Multiple hermetically sealed reed switch outputs are available.

Certifications:

- CSA certified, UL Listed , Class I, Division 2, Groups A,B,C, & D;

- Class II Division 2, Groups F & G.

Switch Options:

- Set Point Accuracy: 2%*

- Interface: 1/2” Conduit / Cable Entry with 16 Position Terminal Strip

- Enclosure: NEMA 4X Rating

- Switch Adjust: Internal to the Enclosure